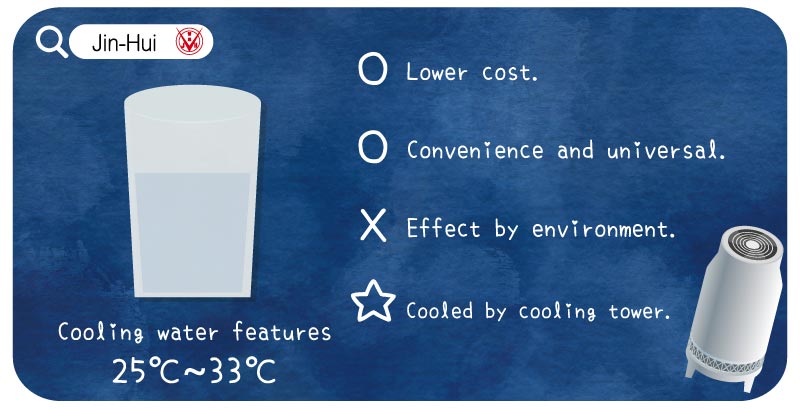

Cooling water

The way to do heat exchange is difference between cooling tower and chiller. The water temperature also difference. Cooling tower is water normally at ambient temperatures arriving from cooling towers. So the capacity of cooling tower is restricted by ambient temperatures (What is wet bulb temperature in cooling tower design?). The process water after cooled by cooling tower we always called it “cooling water”.

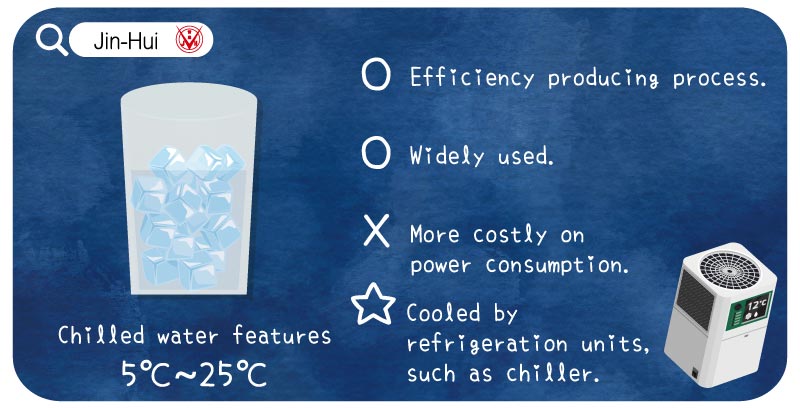

Chilled water

Chilled water is specifically designed according to the process and produced by refrigeration units, which is more complicated and costly than cooling tower. (Working principle of chiller, which is a common used refrigeration units.) The water through refrigeration units cooled we called “chilled water”. The temperature of chilled water can be set usually according the need of process and the area. For example, the chilled water usually set at 5-25 ˚C in Taiwan.

Application difference between cooling water and chilled water

Water adopted in process usually used to shorten the producing cycle and efficiency process. Cool is indispensable and common used in industrial process, such as plastic processing, laser processing, metal finishing, food processing, welding and so on. Even at the same process, difference water adopt will have difference effect on process.

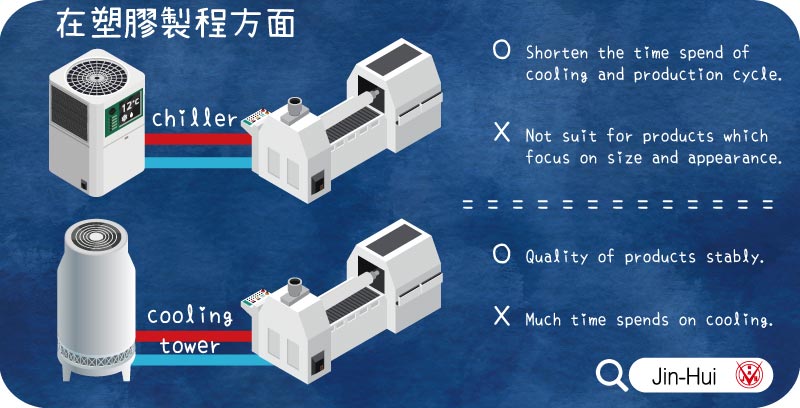

In plastic processing (Working principle of plastic injection)

Cooling water used in plastic processing cooling system is order to make more perfect products and reduce defect rate. Chilled water used in plastic processing is order to gain the better cooling efficiency. Under the same flow condition, the temperature difference between plastic and cooling water can bring more heat out at the moment. In other words, cooling efficiency is upgrade. Chilled water usually be used in thick pieces producing process or speed producing process. To use chilled water has the benefit of shorten manufacturing cycle, but the using of chilled water would cause condensation on the surface of mould. This situation would cause corrosion phenomenon of mould in long-term and shorten the service-life of mould.

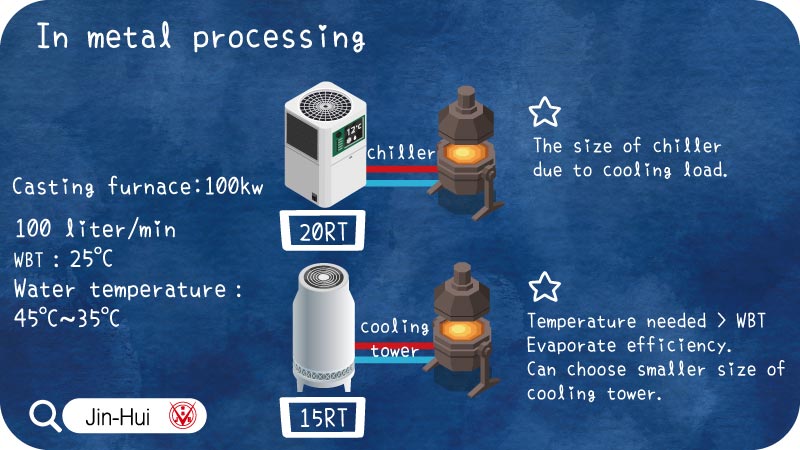

In metal processing

In metal processing, the temperature range is more than plastic processing. Maybe there are some people consider that chilled water is more efficiency than cooling water, but it is a myth. Before you design your cooling system for producing machine you should know two key points below:

1. Heat source in producing process wouldn’t reduce whether use chilled water or cooling water.

2. You should know the temperature condition.

Through the two examples below you can easily understand the difference between cooling tower and chiller in metal processing.

Example 1

There is a casting furnace which is 100kw and the ambient wet bulb temperature is 25˚C.

Today we want to make the process water to cool down the temperature from 45˚C to 35˚C which water flow is 100liter/min.

Condition conclusion as following:

Casting furnace: 100kw

Wet bulb temperature: 25˚C

Water flow rate: 100liter/min

Water inlet temperature: 45˚C

Water output temperature: 35˚C

a. Using chiller to cool down the temperature of process water, you need to use 20RT.

b. If chose cooling tower, just need 15RT cooling tower.

Why has this difference of cooling equipment?

It is because the capacity of chiller is fixed. The heat need to be absorbed completely by chiller. Cooling tower working principle relies on ambient wet bulb temperatures (Cooling tower working principle), when the higher water temperature need to be cooled the more efficiency of cooling tower. Therefore, at the same calories situation, the smaller cooling tower you can chose than chiller.

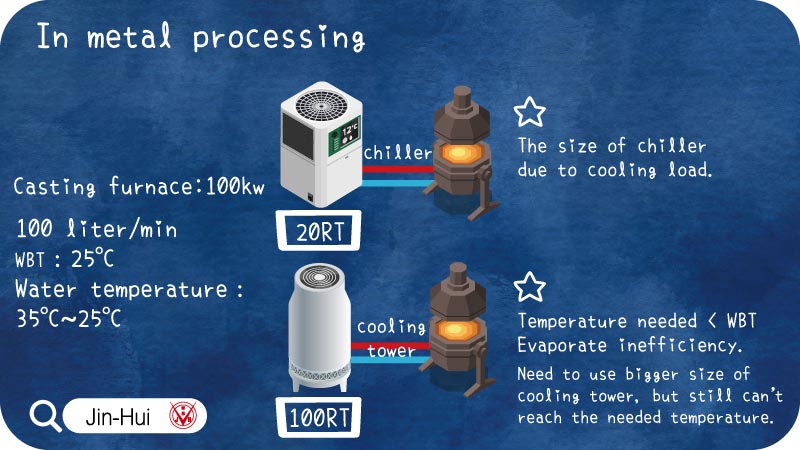

Example 2

The situation of example 2 is the same with example 1. The temperature request is changed, in this case the process water wants to cool down temperature from 35˚C to 25˚C.

Condition conclusion as following:

Casting furnace: 100kw

Wet bulb temperature: 25˚C

Water flow rate: 100liter/min

Water inlet temperature: 35˚C

Water output temperature: 25˚C

a. Using chiller to cool down the temperature of process water, 20RT chiller is enough to reach the temperature request.

b. If chose cooling tower, the temperature is reluctantly to remain at 25˚C even couldn’t cool down the temperature to 25˚C. Though the power consumption of 100RT cooling tower is lower than 20RT chiller, the stable operating of equipment is terrible.

In conclusion, chose chiller or cooling tower is consider the needed of producing process. If the temperature condition is accept to use cooling tower that would be an energy saving project. But, the producing process is special also need the stable and more colder water to support the producing machine operating normally, chiller is the better choice. This is through rich experience to get, so an experienced cooling expert is better choice for your industrial cooling system and JH COOLING MACHINE is best choice for you.

JIN HUI COOLING MACHINE CO., LTD. has over 30 years experienced in industrial cooling systems and is also the first manufacturer of closed circuit cooling towers in Taiwan. Contact JH.

English (UK)

English (UK)  简体中文(中国)

简体中文(中国)  日本語 (Japan)

日本語 (Japan)  繁體中文(台灣)

繁體中文(台灣)