Chiller is commonly used in most process cooling applications including injection molding, chemicals, lasers, machine tools, semi-conductors and more. Industrial chillers are used in a variety of applications. Why can chillers do refrigerating? Chillers through the phase transfer of refrigerant to do refrigerating. The phase transfer of refrigerant means the heat transfer and through this way can reject the heat which is in the object fluid.

How does a chiller work?

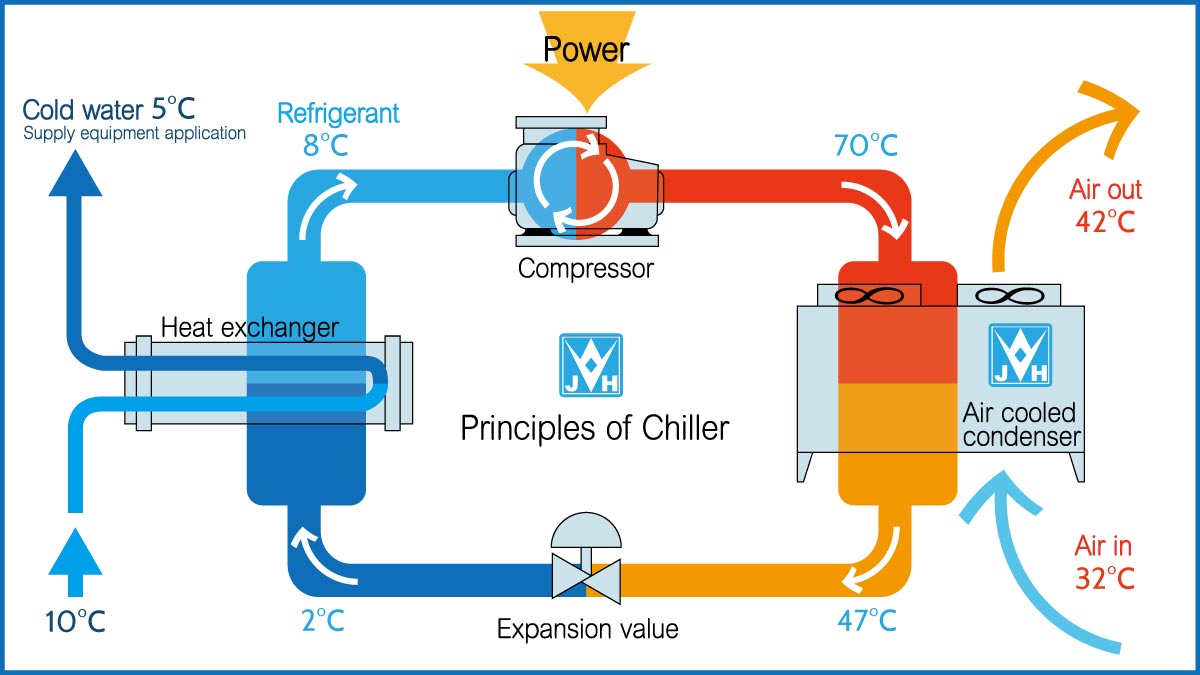

Chiller has four basic components that contain a compressor, condenser, expansion valve and evaporator. Compressor: just like the heart of a chiller that provides power for cooling circulation transfer low-pressure gas into high-pressure gas. The high-pressure gas enters the condenser where the gas removes heat to cool to high-pressure liquid. The high-pressure liquid enters to the expansion valve, which controls how much liquid refrigerant enters the evaporator. After the low-pressure refrigerant enters the evaporator, the heat from the process water will boil. The refrigerant changes it to a low-pressure gas and begins a new refrigeration cycle again.

Basic structure of chiller

Refrigerants are an indispensable element of a chiller. Refrigerants used to transfer heat also a working fluid which has a freeze effect. Besides, chillers have four basic components that contain compressor, condenser, expansion valve and evaporator.

Compressor

A compressor provides power to the refrigerating cycle that increases the pressure of a gas by reducing its volume.

Condenser

Reducing a gas or vapor to a liquid and condenses the refrigerant. There are two types of condenser: air cooled condenser and water cooled condenser.

Expansion valve

Expansion valve is a component in the chiller that controls the amount of refrigerant released into the evaporator to regulate the vapor leaving the evaporator.

Evaporator

Evaporator used to turn the liquid into vapor to absorb the heat and make target water getting colder. The temperature of the evaporator will vary with the evaporation pressure.

JH Industrial Chiller

According to the cooling way, can divide into two types of chiller air cooled chiller and water cooled chiller. Air cooled chiller equips with one set fan system to help reject heat. Water cooled chiller equips with one set cooling tower to help condenser to do heat dissipation.

What chiller best for your process?

Chiller systems are commonly used so have vastly size and design for smaller applications or large central chillers to provide cooling for processes.

JIN HUI COOLING MACHINE CO., LTD. has over 30 years experienced in industrial cooling systems and is also the first manufacturer of closed circuit cooling towers in Taiwan. Contact us.

English (UK)

English (UK)  简体中文(中国)

简体中文(中国)  日本語 (Japan)

日本語 (Japan)  繁體中文(台灣)

繁體中文(台灣)

Industrial Water Cooled Chiller Products

Industrial Water Cooled Chiller Products Industrial Air Cooled Chiller Products

Industrial Air Cooled Chiller Products