DESCRIPTION

The FCR Series Air-Cooled Chillers are a series of air-cooled chillers with CE-certified specifications, and they are designed for industrial environments. All the core parts and components of these box-type chillers are protected inside its casing. For longer, stable operation, the FCR Series Chillers use compressors and expansion valves imported from major overseas manufacturers. In addition, their outer casing and expansion water tank are made of SUS#304 stainless steel, while the inner and outer layers of their expansion water tank are insulated with PU foam which ensures the best chilled water insulation effect. Electric fans in these chillers are designed to blow upward, where double-sided air intake can increase heat dissipation area. These chillers also consist of a microcomputer-based IC control panel, which enables problems to be solved in an easy and quick manner if the chiller encounters any unexpected situation.

SPECIFICATION

|

Model |

Refrigerating capacity |

Rated power |

Compressor horsepower |

Fan horsepower |

Fan blade |

Amount of wind arranged |

Pump horsepower |

Ice water cool water flow |

Cold water pressure |

Pipe |

Weight |

Size |

|||

| kcal/h-50Hz | kcal/h-60Hz | KW | HP | HP | inch | CMM | HP | inch | L/min | inch | kg | (L*W*H) mm | |||

| FCR-110 | 2,520 | 3,024 | 1.25 | 1 | 1/3 | 18" | 65 | 1/2 | 60 | 1.2~2 | 1" | 130 | 820*650*1100 | ||

| FCR-120 | 5,040 | 6,048 | 2 | 2 | 1/3 | 18" | 65 | 1/2 | 60 | 1.2~2 | 1" | 150 | 820*650*1100 | ||

| FCR-130 | 7,560 | 9,073 | 3 | 3 | 1/2 | 24" | 130 | 1/2 | 120 | 1.2~2 | 1" | 230 | 900*880*1580 | ||

| FCR-150 | 12,600 | 15,120 | 5 | 5 | 1/2 | 24" | 130 | 1 | 120 | 1.2~2 | 1" | 280 | 900*880*1580 | ||

| FCR-750 | 18,900 | 22,682 | 8 | 7-1/2 | 1/2*2 | 24"*2 | 260 | 2 | 200 | 1.2~2 | 1-1/2" | 380 | 1670*880*1770 | ||

| FCR-1000 | 25,200 | 30,242 | 10 | 10 | 1/2*2 | 24"*2 | 260 | 2 | 200 | 1.2~2 | 1-1/2" | 450 | 1670*880*1770 | ||

| FCR-1500 | 37,800 | 45,363 | 14 | 15 | 1*2 | 28"*2 | 280 | 2 | 200 | 1.2~2 | 2" | 600 | 1960*1060*1960 | ||

| FCR-2000 | 50,400 | 60,480 | 18 | 20 | 1*2 | 28"*2 | 280 | 2 | 200 | 1.2~2 | 2" | 800 | 1960*1060*1960 | ||

| FCR-2500 | 63,000 | 75,600 | 23 | 12.5*2 | 1*3 | 28"*3 | 420 | 3 | 320 | 1.2~2 | 2-1/2" | 880 | 2620*1120*1980 | ||

| FCR-3000 | 75,600 | 90,720 | 27 | 15*2 | 1*3 | 28"*3 | 450 | 3 | 320 | 1.2~2 | 2-1/2" | 980 | 2620*1120*1980 | ||

| FCR-4000E | 100,000 | 120,000 | 38 | 20*2 | 1*6 | 28"*6 | 830 | 5 | 480 | 1.2~2 | 3" | 1,400 | 2620*2000*1980 | ||

| FCR-5000E | 126,000 | 152,000 | 47 | 25*2 | 1*8 | 28"*8 | 1,100 | 5 | 530 | 1.2~2 | 3" | 1,600 | 3480*2000*1980 | ||

| FCR-6000 | 151,000 | 182,000 | 55 | 30*2 | 1*8 | 28"*8 | 1,100 | 5 | 580 | 1.2~2 | 3" | 1,800 | 3480*2000*1980 | ||

| FCR-6000E | 151,000 | 182,000 | 55 | 30*2 | 1*8 | 28"*8 | 1,100 | 5 | 580 | 1.2~2 | 3" | 1,800 | 3480*2000*1980 | ||

| FCR-7000E | 176,666 | 212,000 | 58.5 | 35*2 | 1*8 | 30"*8 | 1,680 | 650 | 1.2~2 | 4" | 2,000 | 3860*2100*2030 | |||

| FCR-8000E | 201,666 | 242,000 | 66 | 40*2 | 1*8 | 30"*8 | 1,680 | 800 | 1.2~2 | 4" | 2,200 | 3860*2100*2030 | |||

| FCR-100HE | 252,500 | 303,000 | 81 | 50*2 | 1*8 | 30"*8 | 1,680 | 1000 | 1.2~2 | 4" | 2,500 | 3860*2100*2030 | |||

| FCR-120HE | 302,400 | 360,880 | 98 | 60*2 | 1-1/4*8 | 30"*8 | 2,000 | 1100 | 1.2~2 | 5" | 2,700 | 3860*2100*2030 | |||

|

|||||||||||||||

DETAILS

IC Micro-computer temperature control & Touch sensing control panel

The microcomputer-based IC control panel features for simple switch control comprising more than 20 types of fault displays, which can help customers solve problems quickly (depending on model). At the same time, the control panel allows for CE specifications to be customized in order to meet specifications in different countries.

The microcomputer-based IC control panel features for simple switch control comprising more than 20 types of fault displays, which can help customers solve problems quickly (depending on model). At the same time, the control panel allows for CE specifications to be customized in order to meet specifications in different countries.

SUS#304 Stainless steel expansion water tank

SUS #304 Stainless Steel Expansion Water Tank - Its inner and outer layers are made of stainless steel plates, which enables the tank to last longer. PU foam insulation in its inner layer also keeps water cold as it is able to keep ice water well insulated.

SUS #304 Stainless Steel Expansion Water Tank - Its inner and outer layers are made of stainless steel plates, which enables the tank to last longer. PU foam insulation in its inner layer also keeps water cold as it is able to keep ice water well insulated.

World-class compressor & expansion valve

These JH Chillers use compressor brands Maneurop from France and Copeland from the U.S., and comprise expansion valves and various parts which are produced by renowned overseas manufacturers with high reliability.

These JH Chillers use compressor brands Maneurop from France and Copeland from the U.S., and comprise expansion valves and various parts which are produced by renowned overseas manufacturers with high reliability.

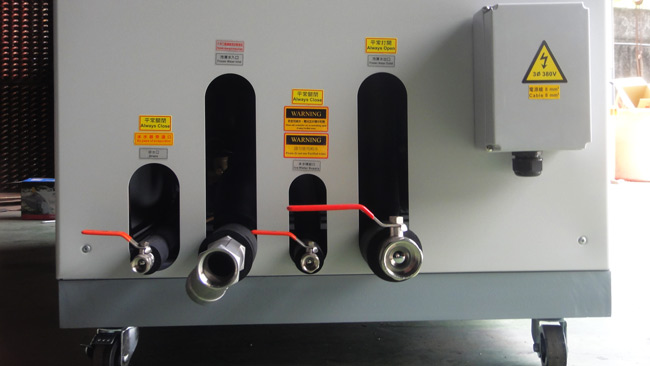

The inlet and outlet

JH will design water inlets and outlets according to customer needs, with a view to manufacturing a chiller which best meets customer needs.

JH will design water inlets and outlets according to customer needs, with a view to manufacturing a chiller which best meets customer needs.

CONTACT NOW!

English (UK)

English (UK)  简体中文(中国)

简体中文(中国)  日本語 (Japan)

日本語 (Japan)  繁體中文(台灣)

繁體中文(台灣)